Getting an accurate construction equipment appraisal can mean the difference between thousands of dollars in your pocket or significant financial losses. Whether you need an appraisal for insurance, financing, or sale purposes, the accuracy of your valuation depends heavily on your preparation and appraiser selection.

Construction equipment appraisals typically cost between $500 to $15,000 depending on complexity, but an inaccurate appraisal can cost you far more. The key lies in understanding what makes an appraisal reliable and taking the right steps before, during, and after the process.

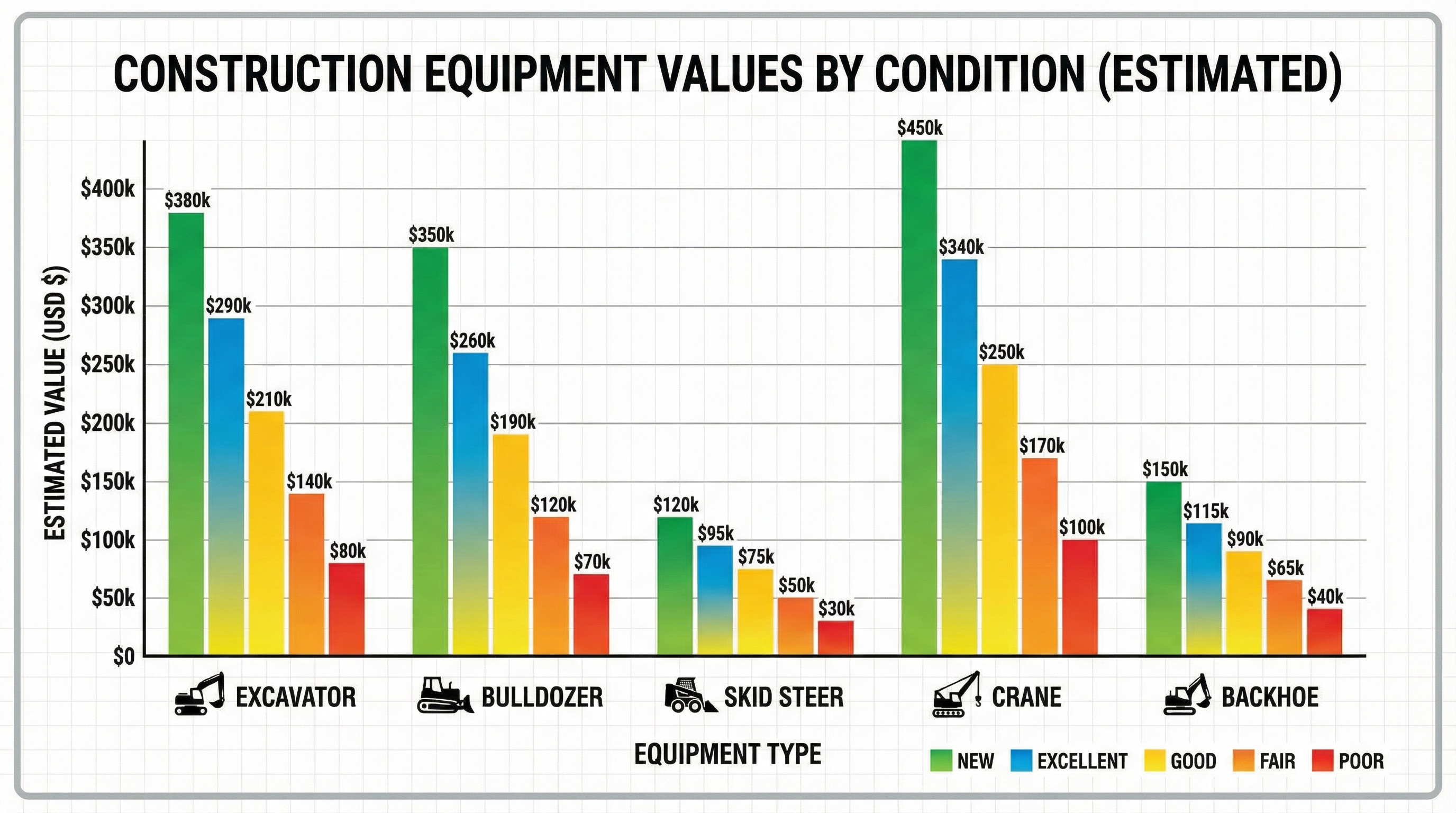

Quick Fact: Equipment condition, age, manufacturer, and local market demand are the primary factors that determine your construction equipment's fair market value.

Finding a qualified appraiser is your first and most critical step toward an accurate valuation. You want someone who understands both the construction industry and current market conditions for heavy machinery.

Look for appraisers with certified credentials from recognized organizations like the American Society of Appraisers or similar professional bodies. These credentials demonstrate that the appraiser has met specific education and experience requirements. More importantly, seek out appraisers who specialize specifically in construction equipment rather than general machinery appraisers.

Experience in your local market matters significantly. An appraiser familiar with regional demand patterns, seasonal fluctuations, and local dealer networks will provide more accurate valuations than someone working from national averages alone. When choosing the right appraiser for construction equipment, ask potential appraisers about their recent experience with equipment similar to yours and request references from past clients.

The best appraisers will also be willing to explain their methodology and provide detailed reports that break down how they arrived at their final valuation. This transparency helps ensure you understand the reasoning behind your appraisal value.

Your preparation directly impacts appraisal accuracy. The more detailed information you provide, the better your appraiser can assess true market value.

Start by gathering basic equipment details including make, model, year of manufacture, serial numbers, and current hour readings. Document any modifications, attachments, or special features that might affect value. Service records and maintenance history provide crucial insights into equipment condition and remaining useful life.

Essential DocumentationWhy It MattersService recordsShows maintenance quality and frequencyHour meter readingsIndicates usage intensity and wearRepair historyReveals potential ongoing issuesPurchase receiptsEstablishes original cost basis

Take clear, high-quality photos of your equipment from multiple angles. Include close-ups of any damage, wear patterns, or unique features. Photos of serial number plates, control panels, and attachment points help appraisers verify specifications and assess condition remotely if needed.

Don't forget to document the equipment's current location and accessibility. Transportation costs and site conditions can influence both the appraisal process timeline and final valuation, especially for larger machinery. For more detailed guidance, review our comprehensive guide on how to prepare for a construction equipment appraisal.

Pro Tip: Organize all documentation in a single folder before contacting appraisers. This preparation speeds up the process and demonstrates your professionalism to potential appraisers.

Construction equipment values fluctuate based on several interconnected factors. Understanding these elements helps you set realistic expectations and identify opportunities to maximize your equipment's appraised value.

Age and condition represent the most obvious value drivers, but they interact in complex ways. A well-maintained 10-year-old excavator might appraise higher than a poorly maintained 5-year-old unit of the same model. Usage patterns matter more than simple age calculations.

Market demand varies significantly by equipment type and geographic region. Specialized equipment like tower cranes or tunneling machines may have limited but high-value markets, while general earthmoving equipment faces broader competition. Your appraiser should understand these market dynamics and factor them into their valuation approach, as explained in our article about understanding the process of a construction equipment appraisal.

Manufacturer reputation and parts availability also influence long-term value retention. Equipment from manufacturers with strong dealer networks and readily available parts typically maintains value better than orphaned brands or discontinued models.

Economic conditions in the construction industry directly impact equipment demand and pricing. During construction booms, used equipment values rise as contractors expand fleets quickly. Conversely, economic downturns can depress values as contractors sell excess capacity.

Market Insight: Local infrastructure projects and seasonal construction patterns can create temporary value fluctuations of 10-15% for specific equipment types in regional markets.

Understanding the appraisal timeline and process helps you plan effectively and avoid unnecessary delays. Most construction equipment appraisals take between one to five days, depending on equipment complexity and quantity.

Single-machine appraisals for common equipment like excavators or bulldozers typically complete within one to two days. Complex machinery with specialized attachments or entire fleet appraisals may require a week or more. Remote locations or scheduling conflicts can extend timelines further.

Prepare your equipment for inspection by ensuring easy access and safe working conditions. Clean equipment presents better and allows appraisers to assess condition more accurately. Have all documentation organized and readily available when the appraiser arrives.

During the inspection, be available to answer questions about equipment history, usage patterns, and any issues the appraiser might identify. Your insights help the appraiser understand factors that might not be immediately visible but could affect value. Learn more about what you should expect when getting a construction equipment appraisal.

After the inspection, most appraisers provide preliminary findings within a few days, followed by a formal written report within one to two weeks. Review this report carefully and ask questions about any valuations or methodologies you don't understand.

The appraisal process works best when you maintain open communication with your chosen appraiser throughout. Clear expectations about timeline, deliverables, and costs prevent misunderstandings and ensure you receive the accurate valuation you need for your specific purpose.

Getting an accurate construction equipment appraisal requires careful preparation, smart appraiser selection, and active participation in the process. By following these strategies, you position yourself to receive reliable valuations that serve your business needs effectively. Understanding the benefits of appraising construction equipment before selling can help you maximize your return on investment. At AppraiseItNow, our experienced appraisers understand the complexities of construction equipment valuation and work with you to ensure accurate, defensible results for any purpose.

Look for appraisers with certified credentials from recognized organizations like the American Society of Appraisers (ASA) or the National Equipment Appraisers Association (NEAA). They should have specific experience with construction equipment rather than general machinery, understand local market conditions, and be willing to explain their methodology. USPAP certification is also important for ensuring professional standards are met.

Construction equipment appraisals typically cost between $500 to $15,000 depending on the complexity, number of machines, and type of inspection required. Single-machine appraisals for common equipment like excavators or bulldozers are on the lower end, while complex machinery with specialized attachments or entire fleet appraisals can cost significantly more.

Essential documentation includes make, model, year, serial numbers, current hour readings, service records, maintenance history, repair records, and purchase receipts. Take clear photos from multiple angles showing any damage or unique features. Also document the equipment's current location and accessibility, as transportation costs can influence the final valuation.

Most construction equipment appraisals take between one to five days, depending on equipment complexity and quantity. Single-machine appraisals for common equipment typically complete within one to two days, while complex machinery or fleet appraisals may require a week or more. After inspection, appraisers usually provide preliminary findings within a few days and a formal written report within one to two weeks.