<h2>Understanding the Value of a Haas VF-4 CNC Mill</h2>

<p>When it comes to precision manufacturing equipment, the <strong>Haas VF-4</strong> stands out as a workhorse in metalworking shops across the country. Whether you're considering selling your machine, buying one for your facility, or determining its value for insurance purposes, understanding the factors that drive pricing is essential.</p>

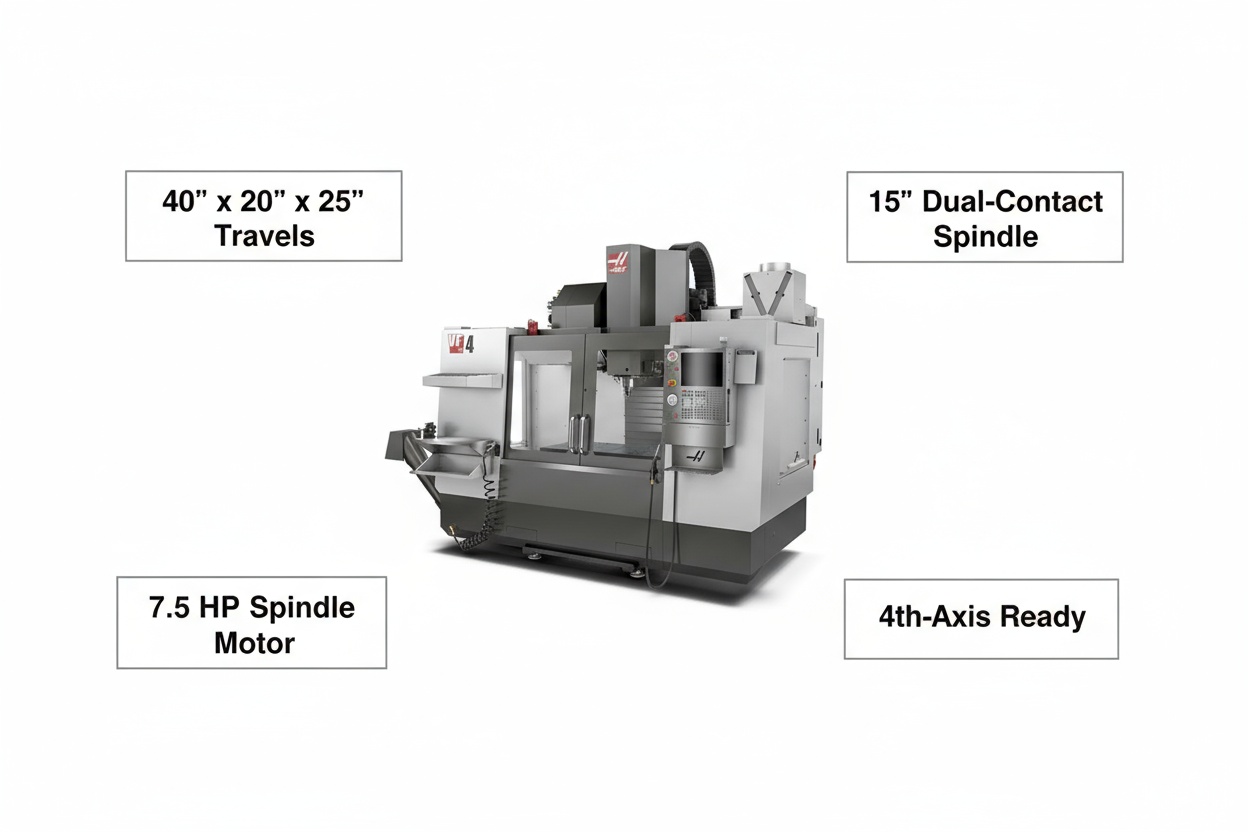

<p>The <strong>Haas VF-4</strong> is a 3-axis vertical machining center that combines rigidity with versatility. Known for its <strong>15-inch dual-contact spindle</strong> and <strong>7.5 HP spindle motor</strong>, this machine excels at prototyping, small-batch production, and specialty machining work. But what makes it valuable? The answer lies in a combination of its robust build quality, precision capabilities, and the condition of your specific unit.</p>

<div class="callout tip"><p><strong>Pro Tip</strong></p>

<p>Before you engage with buyers, sellers, or insurers, gather your machine's service records, spindle hours, and a list of installed options. This documentation speeds up appraisals and often leads to better valuations.</p></div>

<h2>How Accurate Is the Haas VF-4?</h2>

<p>Precision is a cornerstone of <strong>CNC machining</strong>, and the Haas VF-4 delivers on that front. The machine offers consistent tolerance control and reliable 3-axis accuracy, making it suitable for demanding applications. However, accuracy isn't just about the machine's design—it depends heavily on maintenance, spindle condition, and regular calibration.</p>

<p>When you're evaluating a <strong>Haas VF-4</strong> for purchase or appraisal, accuracy testing becomes critical. Look for documentation of recent tolerance testing, service records that show regular spindle maintenance, and any history of axis backlash or runout issues. A machine with a clean maintenance log and low spindle hours will maintain tighter tolerances than one that's been run hard without proper care.</p>

<p>If you're curious about what accuracy looks like in practice, request sample parts or test cuts from the machine. A seller willing to provide these is often demonstrating confidence in their equipment's performance. This kind of transparency helps appraisers establish a more precise market valuation.</p>

<h2>What Does VF Stand for in Haas Machines?</h2>

<p>The <strong>VF</strong> designation stands for <strong>Vertical Format</strong>—indicating that this is a vertical spindle configuration, as opposed to horizontal machines. This matters because vertical mills are the most common type found in general manufacturing shops. The VF-4 specifically denotes the fourth generation or model variant within Haas's vertical format lineup.</p>

<p>Understanding the machine's designation helps you communicate accurately with appraisers, potential buyers, and sellers. When you're researching <strong><a href="/types/equipment-and-machinery">equipment and machinery appraisals</a></strong>, knowing these designations ensures you're comparing apples to apples.</p>

<div class="callout info"><p><strong>Did You Know?</strong></p>

<p>The VF-4 remains one of the most popular Haas CNC machines on the market, which means parts availability is excellent and resale demand stays relatively strong.</p></div>

<h2>What Factors Most Affect the Value of Your Haas VF-4?</h2>

<p>The market value of a <strong>Haas VF-4</strong> isn't determined by a single factor. Instead, it's a combination of elements that appraisers evaluate together:</p>

<p><strong>Machine Condition & Hours</strong><br />

Spindle hours are perhaps the single most important metric. A low-hour machine commands premium prices, while high-hour units drop significantly in value. Even a "well-maintained" machine with 15,000 spindle hours will be worth less than an identical model with 5,000 hours.</p>

<p><strong>Maintenance Records</strong><br />

Documentation matters enormously. Machines with complete service histories, regular spindle maintenance logs, and proof of professional servicing are valued 15–25% higher than those with no records. We often see sellers hesitant to share maintenance logs, but transparency here builds buyer confidence and supports higher valuations.</p>

<p><strong>Controller & Software Version</strong><br />

The <strong>Haas NGC Control</strong> that comes on your VF-4 may be an older or newer version. Updated controllers with the latest software offer better compatibility with modern tooling, faster processing, and fewer compatibility headaches. Older controllers can reduce value, though they're rarely deal-breakers for buyers.</p>

<p><strong>Installed Options</strong><br />

A <strong>4th-axis ready</strong> configuration, automatic tool changers, probe systems, and other accessories increase value. Machines equipped with these options can be worth $5,000–$15,000 more than base models.</p>

<p><strong>Cosmetic & Structural Condition</strong><br />

Beyond the mechanics, buyers notice wear and tear. Rust, paint chips, worn ways, and cosmetic damage reduce perceived value and can signal neglect. A machine that's been kept in a climate-controlled environment typically appraises higher than one stored in a damp garage.</p>

<p><strong>Included Tooling & Fixturing</strong><br />

Quality end mills, holders, fixtures, and collets that come with the machine add real value. A buyer avoiding the need to purchase a complete tooling setup will pay more.</p>

<p><strong>Market Demand & Location</strong><br />

Geographic location and current market demand affect pricing. In areas with strong manufacturing activity, machines move quickly and command higher prices. Shipping costs also factor in—a machine in a central location is more valuable than one requiring expensive logistics.</p>

<h2>Current Market Pricing for the Haas VF-4</h2>

<p>Used <strong>Haas VF-4</strong> mills typically range between <strong>$25,000 and $90,000</strong>, depending on the factors we've discussed. A well-maintained, low-hour machine with current controls and popular options lands in the <strong>$45,000–$55,000 range</strong>. Heavily used machines or those requiring reconditioning may be priced closer to $25,000–$35,000. Fully refurbished units or those with extensive upgrades can exceed $70,000.</p>

<p>These are market observations—your specific machine's value requires a professional appraisal. That's where <strong><a href="/blog/the-basics-of-equipment-and-machinery-appraisal">professional equipment and machinery appraisal services</a></strong> become invaluable.</p>

<div class="callout note"><p><strong>Important</strong></p>

<p>Current prices reflect recent market conditions, but values shift with demand, replacement costs, and economic cycles. An appraisal done today may differ from one done a year ago.</p></div>

<h2>How Do I Know if My Haas VF-4 Needs Repairs Before Selling?</h2>

<p>If you're planning to sell, you need to know what condition issues exist before marketing the machine. This protects you legally and sets buyer expectations accurately. Here's what to assess:</p>

<ol>

<li>

<p><strong>Spindle Health</strong> – Listen for unusual noise during operation. Spindle bearings that are wearing out produce grinding or squealing sounds. High spindle runout (checking with a dial indicator) signals bearing wear.</p>

</li>

<li>

<p><strong>Axis Movement</strong> – Check all three axes for smooth, consistent movement. Backlash (play) in any axis indicates wear on ball screws or bearings.</p>

</li>

<li>

<p><strong>Coolant & Hydraulic Systems</strong> – Look for leaks around the spindle, ways, and hydraulic lines. Seals that need replacement can be a $2,000–$5,000 repair.</p>

</li>

<li>

<p><strong>Control Errors</strong> – Power up the machine and run through a cycle. Any error messages on the screen indicate control or sensor issues.</p>

</li>

<li>

<p><strong>Tolerance Testing</strong> – Run sample parts through the machine. Use a precision caliper or micrometer to check tolerances. Machines that are trending out of spec may have axis issues or spindle wear.</p>

</li>

<li>

<p><strong>Vibration & Noise</strong> – Excessive vibration during cutting suggests structural wear, bearings, or spindle issues.</p>

</li>

</ol>

<p>Document everything. If repairs are needed—and they often are on older machines—disclose them to appraisers and buyers. A $5,000 spindle bearing replacement that you disclose honestly costs you less in valuation than one a buyer discovers during their inspection.</p>

<h2>Getting a Professional Appraisal for Your Haas VF-4</h2>

<p>If you need an accurate, defensible valuation for your <strong>Haas VF-4</strong>—whether for selling, buying, insurance, or legal purposes—a professional appraisal is your best tool. Here's what to expect and what you'll need to provide:</p>

<p><strong>Information to Gather</strong></p>

<p>Before contacting an appraiser, compile:

- Model number and serial number (found on the machine's nameplate)

- Year of manufacture

- Total spindle hours (from the machine's hour meter)

- Controller type and software version

- List of all installed options (4th axis, tool changer, probe, etc.)

- Complete maintenance and service records

- Recent test cuts or tolerance reports

- High-quality photos of the entire machine, serial plate, and control panel</p>

<p><strong>The Appraisal Process</strong></p>

<p>A <strong>USPAP-compliant appraiser</strong>—certified through organizations like the <strong>American Society of Appraisers (ASA)</strong> or <strong>International Society of Appraisers (ISA)</strong>—will review your documentation and either conduct an in-person inspection or evaluate detailed photos and reports you submit. Learn more about <strong><a href="/blog/appraising-industrial-equipment-assessing-machinery-and-manufacturing-assets">appraising industrial equipment and assessing machinery</a></strong> to understand the depth of analysis involved.</p>

<p>The appraiser will compare your machine to recent sales of similar units, factor in condition and hours, and produce a detailed report that stands up in legal, financial, and insurance contexts.</p>

<p><strong>Online vs. In-Person Appraisals</strong></p>

<p>Many appraisal platforms now offer <strong>online appraisal services</strong> where you submit photos, specs, and documentation remotely. This works well for straightforward valuations and saves time. For machines with condition concerns or high values, an in-person inspection may provide more confidence in the final number.</p>

<div class="callout tip"><p><strong>Pro Tip</strong></p>

<p>If you're selling privately, a professional appraisal gives you a strong negotiating position and answers buyer questions before they arise.</p></div>

<h2>Where Are the Best Places to Sell a Used Haas VF-4?</h2>

<p>Once you have an appraisal and understand your machine's value, you need to reach the right buyers. Here are your main options:</p>

<p><strong>Industry Marketplaces</strong><br />

Platforms like <strong>MachineTools.com</strong> and <strong>MachineryTrader.com</strong> attract serious manufacturing buyers actively seeking equipment. These sites let you list detailed specs, upload photos, and reach a national audience. Listings with clear photos, complete specs, and service history attract more qualified inquiries.</p>

<p><strong>Haas Dealers & Trade-Ins</strong><br />

Local Haas dealers often accept used equipment as trade-ins on new machines. While you might not get top dollar this way, the process is straightforward and quick. Some dealers also resell used equipment, which can work in your favor if your machine meets their quality standards.</p>

<p><strong>Equipment Brokers & Auctioneers</strong><br />

Specialized brokers and auction houses that focus on <strong><a href="/types/heavy-machinery">heavy machinery</a></strong> and <strong><a href="/types/metalworking-equipment">metalworking equipment</a></strong> have established buyer networks. They handle logistics, marketing, and negotiation—for a commission, typically 10–15% of the sale price.</p>

<p><strong>Local Equipment Auctions</strong><br />

Regional auctions attract local buyers and can move equipment quickly. The downside is you typically get less money, but the speed might justify it if you're in a hurry.</p>

<p><strong>Industry Forums & Networks</strong><br />

Posting in machining forums, Facebook groups, or LinkedIn can reach buyers without middlemen. Be prepared to answer lots of questions and arrange viewings.</p>

<p><strong>Key Listing Tips</strong><br />

Regardless of where you sell, provide:

- Multiple high-quality photos from different angles

- Exact spindle hours and year

- Complete list of options and accessories

- Links to or copies of service records

- Disclosure of any known issues</p>

<p>Transparency accelerates sales and often brings better offers.</p>

<h2>Is Buying a Used Haas VF-4 a Good Investment for a Small Shop?</h2>

<p>If you're on the buying side, a used <strong>Haas VF-4</strong> can be an excellent investment—but only if you approach it strategically. Here's what to consider:</p>

<p><strong>Advantages</strong><br />

A well-maintained VF-4 offers solid accuracy, proven reliability, and strong resale value down the road. Parts and tooling are readily available, and the machine has a reputation in the industry. For many shop tasks—prototype work, small batches, specialty jobs—it's the right tool at a fraction of new machine costs.</p>

<p><strong>Hidden Costs</strong><br />

Budget for potential repairs. A spindle bearing replacement, control upgrades, or way restoration might cost $3,000–$10,000. Factor these into your purchase decision. Also consider: installation and setup, electrical work, training, and spare parts inventory.</p>

<p><strong>Control Version Matters</strong><br />

Older controllers may struggle with modern CAM software or probing systems. Understanding the machine's control generation helps you assess compatibility with your workflow.</p>

<p><strong>Pre-Purchase Inspection</strong><br />

Before buying, hire an independent inspector or appraiser to examine the machine. This typically costs $500–$1,500 but prevents expensive surprises. Look specifically for spindle condition, axis wear, and control functionality. A machine that tests well is a machine you can rely on.</p>

<div class="callout note"><p><strong>Key Takeaway</strong></p>

<p>A pre-purchase inspection saves money and frustration—treat it as essential due diligence, not an optional expense.</p></div>

<h2>Understanding Different Types of Equipment Appraisals</h2>

<p>If you're new to equipment valuation, it helps to understand that appraisals serve different purposes. For a <strong>Haas VF-4</strong>, you might need:</p>

<ul>

<li><strong>Fair Market Value</strong> – What the machine would sell for between willing buyer and seller in current market conditions. This is typical for selling or buying decisions.</li>

<li><strong>Liquidation Value</strong> – What you'd get if you had to sell quickly, often 40–60% of fair market value. Relevant if you're facing bankruptcy or urgent asset disposition.</li>

<li><strong>Replacement Cost</strong> – What a new VF-4 would cost, used to establish insurance coverage and tax depreciation schedules.</li>

</ul>

<p>Learn more about <strong><a href="/blog/types-of-machinery-and-equipment-appraisals-available">types of machinery and equipment appraisals available</a></strong> to determine which type suits your situation.</p>

<h2>What Information Should You Gather Before Asking for an Appraisal?</h2>

<p>The more documentation you provide, the faster and more accurate your appraisal will be. Create a folder containing:</p>

<ul>

<li><strong>Machine Identifiers</strong>: Model, serial number, year manufactured</li>

<li><strong>Operational Data</strong>: Spindle hours, control software version, any error codes or warnings</li>

<li><strong>Configuration</strong>: List of installed options, tooling included, accessories</li>

<li><strong>Service History</strong>: Maintenance logs, repair records, spindle rebuilds, control upgrades</li>

<li><strong>Performance Documentation</strong>: Recent tolerance tests, sample parts, quality reports</li>

<li><strong>Condition Notes</strong>: Any cosmetic damage, wear areas, or known issues</li>

<li><strong>Photographs</strong>: Clear images of the machine, serial plate, control panel, and any damage</li>

</ul>

<p>Appraisers certified by organizations like the <strong>American Society of Appraisers (ASA)</strong> or <strong>Appraisers Association of America (AAA)</strong> know exactly what to look for and how to interpret this information in a market context.</p>

<h2>How Does Equipment Appraisal Impact Your Tax Status?</h2>

<p>An appraisal affects your taxes in several ways. If you're <strong>deprecating the machine</strong> for business purposes, the appraised value becomes your basis for calculating annual depreciation deductions. If you're donating equipment to a nonprofit, a certified appraisal establishes the charitable deduction amount the IRS will accept.</p>

<p>For <strong><a href="/types/business-assets">business assets</a></strong> and <strong><a href="/types/net-tangible-assets">net tangible assets</a></strong> reporting, accurate equipment valuations are critical. An appraisal that's too high inflates your balance sheet; one that's too low leaves money on the table or creates audit risk.</p>

<p>Consult with your accountant about how a specific appraisal affects your tax situation, but know that professional valuations provide the documentation the IRS expects.</p>

<h2>Comparing the Haas VF-4 to Other Popular CNC Machines</h2>

<p>While the Haas VF-4 is popular, the CNC market includes other strong competitors. Understanding how it stacks up helps you make informed decisions:</p>

<p>The <strong>Haas VF-4</strong> excels at general-purpose work with good speed, rigidity, and spindle power. Its 40" × 20" × 25" travels suit most shop applications. Machines like the <strong>Haas VF-6</strong> offer larger travels and more spindle power, commanding higher prices. Smaller Haas models (the <strong>Haas Mini Mill</strong>) cost less but have limited capacity.</p>

<p>Other brands—<strong>Fadal</strong>, <strong>Mori Seiki</strong>, <strong>Okuma</strong>, <strong>DMG Mori</strong>—each have loyal followings and different pricing dynamics. However, the Haas brand maintains strong resale value and parts availability, which matters when you eventually sell or need service.</p>

<p>For deeper insights into how different equipment stacks up, explore <strong><a href="/blog/common-mistakes-to-avoid-when-getting-an-equipment-and-machinery-appraisal">common mistakes to avoid when getting an equipment and machinery appraisal</a></strong> and <strong><a href="/blog/questions-to-ask-before-getting-an-equipment-and-machinery-appraisal">questions to ask before getting an equipment and machinery appraisal</a></strong>.</p>

<h2>What Is the Lifespan of a Haas CNC Machine?</h2>

<p>A well-maintained <strong>Haas CNC machine</strong> can run reliably for 20–30 years or more. The VF-4 was built to last, with heavy-duty construction and proven designs. However, lifespan depends on:</p>

<ul>

<li><strong>Hours of operation</strong> – More hours equals faster wear on spindle bearings, ball screws, and ways</li>

<li><strong>Maintenance practices</strong> – Regular spindle flushing, coolant changes, and calibration extend life dramatically</li>

<li><strong>Operating conditions</strong> – Humidity, temperature extremes, and dusty environments accelerate wear</li>

<li><strong>Part availability</strong> – As machines age, finding replacement parts becomes harder, which can force retirement even if the machine is mechanically sound</li>

</ul>

<p>A 15-year-old VF-4 with 5,000 spindle hours and perfect maintenance might have another 15 years of life ahead. A 10-year-old machine with 20,000 hours and deferred maintenance might need $10,000 in reconditioning soon.</p>

<p>This is why maintenance records matter so much in appraisals. They tell the story of how the machine has been treated and what you can realistically expect going forward.</p>

<div class="callout info"><p><strong>Did You Know?</strong></p>

<p>Many shops run Haas machines that are 20+ years old and still holding tight tolerances. The brand's reputation for durability supports strong secondary-market demand.</p></div>

<h2>Making the Right Decision: Selling, Buying, or Insuring Your Haas VF-4</h2>

<p>Whether your situation involves selling equipment, acquiring a used machine, or protecting your assets with proper insurance coverage, a professional appraisal provides the foundation for confidence. An appraiser who understands <strong><a href="/blog/what-types-of-metalworking-equipment-are-usually-appraised">metalworking equipment</a></strong> and has experience with CNC machinery will deliver a report that stands up to scrutiny.</p>

<p><strong>For Sellers</strong>: An appraisal justifies your asking price, attracts qualified buyers, and accelerates negotiations.</p>

<p><strong>For Buyers</strong>: A pre-purchase appraisal confirms you're paying fair value and haven't inherited hidden problems.</p>

<p><strong>For Insurance</strong>: A current appraisal ensures your coverage matches actual replacement cost, protecting you if damage occurs.</p>

<p>The <strong>Haas VF-4</strong> remains one of the industry's most reliable vertical mills. Its market value reflects that reputation, but getting a precise figure requires professional evaluation. Understanding the factors that drive value—hours, maintenance, options, condition—helps you make informed decisions whether you're buying, selling, or simply protecting your investment.</p>

<div class="callout note"><p><strong>Key Takeaway</strong></p>

<p>A professional <strong>USPAP-compliant appraisal</strong> backed by a certified appraiser gives you defensible, market-based valuations you can trust for selling, buying, insurance, or tax purposes. Reach out to AppraiseItNow to connect with experienced appraisers who specialize in CNC machinery and industrial equipment.</p></div>