<h2>Understanding Fanuc CNC Mill Robodrill Valuation</h2>

<p>The <strong>Fanuc CNC Mill Robodrill</strong> represents a significant investment for any manufacturing facility. Whether you're planning to sell your unit, purchase a used machine, or establish the value for insurance purposes, understanding what drives the resale market is essential. These precision machining centers command strong demand in secondary markets because of their reputation for reliability and tight tolerances—but price fluctuations depend on multiple technical and market factors.</p>

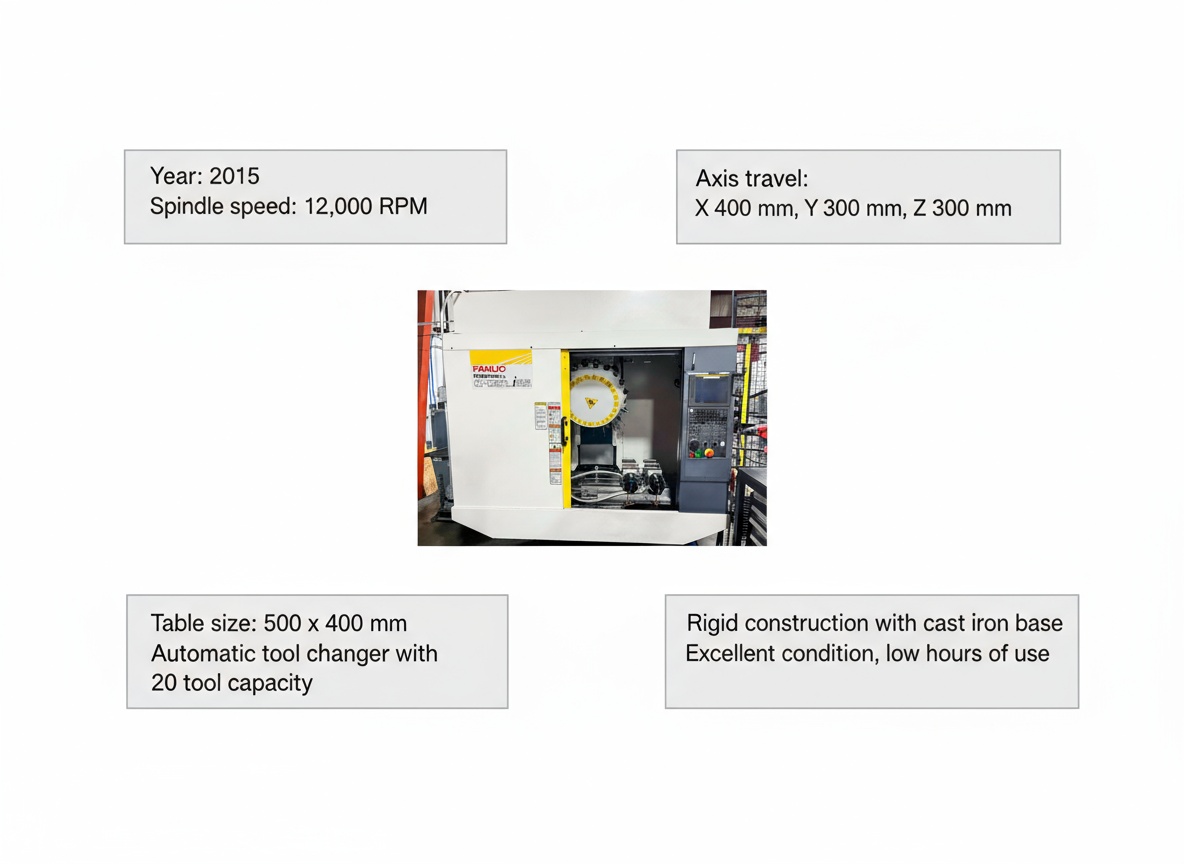

<h2>Key Specs That Define Your Robodrill's Worth</h2>

<p>A typical <strong>Fanuc Robodrill</strong> configuration—such as the ROBODRILL α-DiB3/5C model from 2015—comes equipped with impressive performance characteristics. The machine features a 12,000 RPM spindle, axis travel of X 400 mm, Y 300 mm, and Z 300 mm, and a 500 mm x 400 mm table size with an automatic tool changer holding 20 tools. This rigid construction with a cast iron base ensures stability and longevity when properly maintained.</p>

<p>A unit in excellent condition with low spindle hours typically commands an estimated value between <strong>$80,000 and $110,000</strong>. However, the specific price you'll see depends heavily on:</p>

<ul>

<li><strong>Model and controller version</strong> (older controls reduce value; newer systems add premium)</li>

<li><strong>Spindle hours and maintenance records</strong> (low-hour machines with documented service fetch higher prices)</li>

<li><strong>Tooling and accessories</strong> (complete tool sets and automation features increase desirability)</li>

<li><strong>Cosmetic and structural condition</strong> (rust, crash damage, or worn components lower value significantly)</li>

</ul>

<div class="callout tip"><p><strong>Pro Tip</strong></p>

<p>Keep detailed maintenance records from day one. Buyers and appraisers value machines with documented service histories far more than those with spotty paperwork.</p></div>

<h2>What Factors Most Affect Your Robodrill's Resale Value?</h2>

<p>When appraising industrial equipment like a <strong>Fanuc CNC mill</strong>, experienced professionals examine multiple dimensions. Condition and service history form the foundation—a machine with regular spindle maintenance, coolant changes, and axis calibration records will outperform one with unknown upkeep.</p>

<p>The controller and spindle options matter enormously. Newer control systems that integrate with modern CAM software command premiums; conversely, outdated or proprietary controls can become liability if repair parts grow scarce. Spindle speed, orientation, and any special coatings or upgrades also influence pricing.</p>

<p>Spindle hours tell a critical story. A 2015 Robodrill with 5,000 hours carries far different value than an identical unit with 25,000 hours. Tooling completeness also plays a role—machines sold with all 20 tool positions filled, calibrated, and documented will attract more serious buyers than partially equipped units.</p>

<div class="callout info"><p><strong>Did You Know?</strong></p>

<p>Transport and location significantly impact final selling price. Machines in industrial hubs with concentrated buyer demand often sell 10–15% higher than identical units in remote areas.</p></div>

<p>Documentation gaps, cosmetic damage, or mechanical issues like axis backlash, spindle bearing noise, or control faults will reduce value. A machine showing signs of crash history or coolant damage requires costly repairs that savvy buyers will factor into their offers.</p>

<h2>How to Get a Reliable Valuation for Your Fanuc CNC Robodrill</h2>

<p>Accurate pricing starts with gathering the right information. To get a professional appraisal that reflects current market conditions, compile:</p>

<ol>

<li><strong>Serial number and model designation</strong> (e.g., ROBODRILL α-DiB3/5C)</li>

<li><strong>Year of manufacture</strong> and current spindle hours</li>

<li><strong>High-resolution photographs</strong> (top, side, and close-ups of control panel, spindle, and work surface)</li>

<li><strong>Maintenance and service records</strong> (crucial for credibility)</li>

<li><strong>List of installed options</strong> (rotary tables, pallet changers, coolant systems, software)</li>

<li><strong>Any known issues or recent repairs</strong> (be transparent; appraisers uncover problems anyway)</li>

</ol>

<p>Using a platform that adheres to <strong>USPAP</strong> (Uniform Standards of Professional Appraisal Practice) ensures your appraisal carries legal weight for insurance, lending, or litigation. Credentialed appraisers certified through organizations like the <strong>American Society of Appraisers (ASA)</strong> or the <strong>International Society of Appraisers (ISA)</strong> bring expertise and objectivity that informal estimates cannot match.</p>

<p>For <strong>equipment and machinery appraisals</strong>, an on-site inspection is the gold standard—it allows the appraiser to test spindle runout, check axis smoothness, verify control responsiveness, and spot hidden wear. However, online platforms now allow you to submit photos and documentation securely, which works well for preliminary valuations or when travel is impractical.</p>

<div class="callout note"><p><strong>Key Insight</strong></p>

<p>Getting a certified appraisal before listing your machine often pays for itself by helping you set realistic asking prices that attract qualified buyers quickly.</p></div>

<h2>Robodrill Reliability and Long-Term Value Retention</h2>

<p>One reason the <strong>Fanuc CNC mill Robodrill</strong> holds value so well is its reputation for reliability. With regular maintenance, these machines can operate 10–25+ years without major overhaul. However, mechanical wear, outdated control software, and availability of spare parts do erode value over time.</p>

<p>Is a <strong>FANUC Robodrill</strong> a good investment if you plan to resell? Yes, provided you purchase at a reasonable price and maintain the machine diligently. Standard, well-documented units in the mid-five-figure range tend to sell faster and cleaner than specialized or heavily customized configurations. A refurbished spindle or control system upgrade can restore significant value to an aging machine, so capital spent on preventive maintenance often translates to better resale outcomes.</p>

<p>The secondary market for <strong>FANUC</strong> equipment remains robust because the brand represents precision, uptime, and a deep pool of qualified technicians. Older or more generic CNC mills often struggle to find buyers or command lower prices—so brand reputation genuinely matters.</p>

<h2>Common Issues That Reduce Robodrill Value</h2>

<p>Potential buyers and appraisers watch for specific red flags. Control faults—especially if the system cannot communicate with modern computer networks or requires proprietary software support—significantly diminish value. Spindle wear manifests as bearing noise, runout, or loss of rated RPM; a replacement spindle can cost $10,000–$20,000, which savvy buyers will subtract from their offer.</p>

<p>Axis backlash, coolant or rust damage, crash-related frame distortion, and missing operator or maintenance manuals all reduce asking price. Cosmetic wear (paint chips, worn labels) matters less than structural or mechanical problems requiring costly repairs. An honest assessment of these issues before listing helps you price competitively and avoid surprises during buyer inspections.</p>

<p>For deeper guidance on identifying and documenting equipment condition, explore our resource on <a href="/blog/appraising-industrial-equipment-assessing-machinery-and-manufacturing-assets"><strong>appraising industrial equipment</strong></a> and <a href="/blog/types-of-machinery-and-equipment-appraisals-available"><strong>types of machinery and equipment appraisals available</strong></a>.</p>

<h2>Transportation, Market Demand, and Location Factors</h2>

<p>The final price you receive depends partly on logistics. Rigging, crating, and shipping a <strong>Fanuc CNC mill</strong> adds significant cost—especially if your buyer is across the country or internationally. Customs duties, local tariffs, and crane rental all reduce the net proceeds to the seller.</p>

<p>Machines located in manufacturing-heavy regions (automotive clusters, aerospace hubs, industrial parks) often attract more qualified local buyers, reducing transportation costs and speeding sales. Remote locations or areas with sparse manufacturing activity may require expensive long-distance transport, which depresses the price buyers will pay.</p>

<div class="callout tip"><p><strong>Pro Tip</strong></p>

<p>Factor shipping and rigging costs into your pricing strategy. A machine worth $100,000 at your facility might net only $85,000 after transport if the buyer must pay to move it 1,000 miles.</p></div>

<h2>Why Professional Appraisal Strengthens Your Position</h2>

<p>Whether you're selling, buying, or seeking insurance coverage, a certified <strong>Fanuc CNC mill</strong> appraisal provides defensible documentation of fair market value. For sellers, a professional report justifies asking prices and accelerates buyer confidence. For buyers, an independent appraisal protects against overpayment and uncovers hidden mechanical issues. For insurance purposes, an appraisal ensures your coverage limits match replacement cost.</p>

<p>Our platform connects you with credentialed specialists in industrial equipment valuation who understand the nuances of CNC machinery, spindle technology, and control systems. Learn more about <a href="/blog/the-basics-of-equipment-and-machinery-appraisal"><strong>the basics of equipment and machinery appraisal</strong></a> and <a href="/blog/the-steps-of-a-proper-equipment-and-machinery-appraisal"><strong>the steps of a proper equipment and machinery appraisal</strong></a> to see how the process works.</p>

<p>For specialized appraisals of <a href="/blog/what-types-of-metalworking-equipment-are-usually-appraised"><strong>metalworking equipment</strong></a> and <a href="/types/heavy-machinery"><strong>heavy machinery</strong></a>, our network includes experts certified by the <strong>Association of Machinery and Equipment Appraisers (AMEA)</strong> and other recognized organizations.</p>

<div class="callout note"><p><strong>Key Takeaway</strong></p>

<p>A professional appraisal of your <strong>Fanuc CNC Mill Robodrill</strong> removes guesswork and gives you the confidence to make informed decisions—whether selling, buying, or protecting your asset through proper insurance. Submit your photos, specifications, and service records today to receive a market-backed valuation from certified experts.</p></div>

<hr />

<p><strong>Ready to discover the true value of your Robodrill?</strong> Contact AppraiseItNow for a secure online appraisal or in-person inspection by credentialed specialists who understand industrial machinery inside and out.</p>