<h2>Understanding the Doosan CNC Mill DNM400's Market Value</h2>

<p>The <strong>Doosan CNC Mill DNM400</strong> is a workhorse in the metalworking world. Whether you're a job shop owner considering adding one to your operations, a manufacturer looking to understand your current asset's value, or a business planning an exit strategy, knowing what this machine is actually worth matters. A fair and accurate appraisal of your DNM400 ensures you're making informed decisions—whether that's buying, selling, or protecting your investment through proper insurance coverage.</p>

<h3>What Makes the DNM400 a Valuable Asset?</h3>

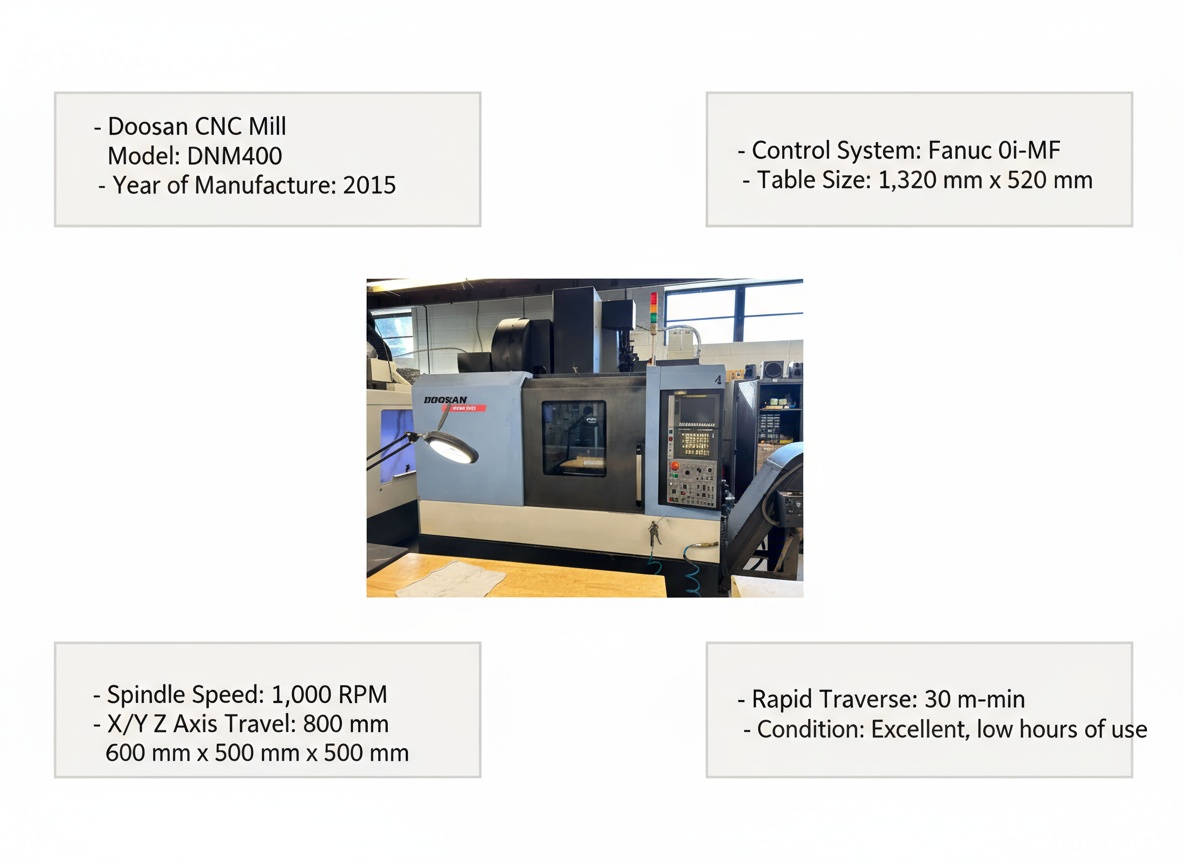

<p>The Doosan DNM400 earned its reputation as a dependable milling center for good reason. Built on a rigid casting design, this machine combines precision with reliability. The <strong>Fanuc 0i-MF control system</strong> gives operators intuitive programming and proven performance, while the <strong>12,000 RPM spindle</strong> handles a wide range of materials and operations. With a table measuring 1,320 mm × 520 mm and solid axis travel, the DNM400 offers flexibility for both small tooling jobs and production runs.</p>

<p>What you should understand is that the machine's physical capabilities tell only part of the value story. When appraisers evaluate a DNM400, they look far beyond the spec sheet. Spindle hours, maintenance records, recent service work, and the availability of replacement parts all factor into your machine's current market position.</p>

<div class="callout tip"><p><strong>Pro Tip</strong></p>

<p>Start gathering your service records, spindle hour logs, and any upgrade documentation now. These details significantly influence your machine's appraised value.</p></div>

<h3>How Much Is Your Doosan DNM400 Worth?</h3>

<p>A <strong>Doosan CNC Mill DNM400</strong> typically ranges from $30,000 to $120,000 in the used market, though machines in excellent condition with low spindle hours often fall between $80,000 and $100,000. That's a broad range—and for good reason. The difference between a well-maintained, low-hour machine and one that has been run hard without records is substantial in buyer perception and actual remaining service life.</p>

<p>Several factors directly influence your machine's value:</p>

<ul>

<li><strong>Year of manufacture</strong> — A 2015 model like many available today sits in a sweet spot of modern control systems and proven reliability</li>

<li><strong>Spindle hours and operational history</strong> — Low-hour machines command premiums because buyers know they have more productive life remaining</li>

<li><strong>Control system type</strong> — Fanuc controls are highly preferred in North America and command better resale value than older proprietary systems</li>

<li><strong>Maintenance documentation</strong> — Machines with verified service records sell faster and at higher prices</li>

<li><strong>Optional equipment</strong> — 4th axis setups, automatic tool changers, or coolant systems add significant value</li>

<li><strong>Overall condition</strong> — Surface rust, worn ways, or spindle issues can reduce value by 20–40%</li>

</ul>

<p>Think of it like buying a used car: two vehicles from the same year and model can have vastly different values based on mileage, service history, and condition. The same principle applies to industrial machinery.</p>

<h3>Key Specifications That Drive Value</h3>

<p>When you're evaluating a DNM400's worth, these specifications matter most to potential buyers and appraisers:</p>

<ul>

<li><strong>Spindle Speed:</strong> 12,000 RPM (suitable for both roughing and finishing work)</li>

<li><strong>Rapid Traverse:</strong> 30 m/min (affects productivity and cycle times)</li>

<li><strong>Axis Travel:</strong> 800 mm (X) × 500 mm (Y) × 500 mm (Z) (defines workpiece envelope)</li>

<li><strong>Control System:</strong> Fanuc 0i-MF (preferred by shops, increases resale value)</li>

<li><strong>Table Size:</strong> 1,320 mm × 520 mm (affects part clamping versatility)</li>

</ul>

<p>The Fanuc control system in particular deserves your attention. Fanuc is the industry standard in North America and Europe. If your DNM400 has been retrofitted with a modern Fanuc or Siemens control, or if you've upgraded the spindle, these enhancements directly increase resale value. Buyers will pay a premium for documented upgrades that reduce downtime and broaden the machine's capabilities.</p>

<div class="callout info"><p><strong>Did You Know?</strong></p>

<p>Control system and spindle upgrades can add $10,000 to $25,000 to a DNM400's resale value—sometimes more if the work is documented and professional.</p></div>

<h3>Why Professional Appraisal Matters for Your DNM400</h3>

<p>You might think you can simply list your machine online and see what similar units are selling for. That approach has limitations. Online listings often reflect asking prices, not actual sale prices. Private sales vary wildly. And if you're appraising your machine for insurance, tax reporting, or a business valuation, you need a certified professional who understands both the equipment and your specific situation.</p>

<p>A professional <a href="https://www.example.com/blog/a-comprehensive-look-at-metalworking-equipment-appraisal">metalworking equipment appraisal</a> follows established standards. Appraisers certified by organizations like the <strong>International Society of Appraisers (ISA)</strong>, <strong>American Society of Appraisers (ASA)</strong>, or <strong>Appraisers Association of America (AAA)</strong> have credentials that hold weight with buyers, lenders, and tax authorities. They conduct thorough condition assessments, review market comparables specific to your machine's configuration, and produce a defensible report.</p>

<p>When you work with a platform like AppraiseItNow, your assignment goes to a credentialed specialist in industrial equipment. You provide clear photographs, specifications, maintenance records, and details about any upgrades or damage. The appraiser analyzes comparable sales, considers regional demand for your machine, and factors in the current used equipment market—which fluctuates based on new machine pricing, economic activity, and availability of parts and service support.</p>

<h3>Preparing Your Machine for Appraisal and Sale</h3>

<p>If you're planning to sell your <strong>Doosan DNM400</strong> or need an appraisal for insurance or financing, take these practical steps:</p>

<ol>

<li><strong>Document everything</strong> — Gather service records, maintenance logs, spindle hour readings, and any upgrade work completed</li>

<li><strong>Take clear photos</strong> — Capture the machine from multiple angles, the control panel, the spindle area, and any visible wear or excellent condition points</li>

<li><strong>Record the specifications</strong> — Note serial number, control type, spindle speed, axis travel, and any optional equipment</li>

<li><strong>List any accessories</strong> — Automatic tool changers, coolant systems, custom fixtures, and tooling can add to your machine's value</li>

</ol>

<p>When considering whether to repair your machine before selling, evaluate the repair cost against the likely increase in sale price. Small, inexpensive fixes—replacing worn seals, updating software, or fixing a probe—often improve marketability and sale price significantly. Major rebuilds, though, may not justify their cost. Get a repair estimate and compare it to the added value you'd gain. Sometimes selling as-is to a buyer who specializes in rebuilds makes more financial sense.</p>

<div class="callout tip"><p><strong>Pro Tip</strong></p>

<p>Minor repairs (under $2,000) usually justify themselves through better sale prices and faster selling. Major work (over $5,000) warrants a comparison: repair cost versus the added sale price, or selling as-is.</p></div>

<h3>Understanding Operating Costs and Machine Lifespan</h3>

<p>When you own or operate a DNM400, understanding the true cost of operation helps you price your jobs accurately and understand your machine's ongoing value. Operating costs typically range from <strong>$20 to $75 per hour</strong> depending on how heavily you use the machine. This includes electricity, routine maintenance, tool wear, coolant, and minor repairs.</p>

<p>High-precision work or intensive production raises costs because you'll consume more inserts, tooling, and fixtures. Track your actual consumables, power usage, and labor to calculate a precise rate. Many shops overlook this—they estimate loosely and leave money on the table. A professional appraisal often includes an operating cost assessment as part of understanding the machine's productive capacity and remaining value.</p>

<p>With proper maintenance, a DNM400 can remain productive for <strong>10 to 20 years</strong> in typical job shop use. The calendar age matters far less than condition and maintenance history. Machines with regular lubrication, way protection, and seasonal service routines often outperform newer machines that have been neglected. If you're buying a used DNM400, ask for maintenance records going back as far as possible. If you're selling, this documentation becomes your strongest sales tool.</p>

<h3>Comparing the DNM400 to Other Milling Options</h3>

<p>You might wonder how the Doosan stacks up against competitors like Haas. While both are quality manufacturers, they serve somewhat different markets. Haas machines are popular in North America for rapid turnaround and ease of programming. Doosan, manufactured primarily in <strong>South Korea</strong>, has a strong reputation for rigid construction and cost-effectiveness. Neither "better"—they're different tools for different applications.</p>

<p>For your appraisal, what matters is that Doosan machines are well-supported across most regions. Parts availability and service technician access affect a machine's practical value. If you're in an area where Doosan support is strong, your machine's value remains solid. If you're in a region with fewer technicians or parts suppliers, resale value may soften slightly. A professional appraiser understands these regional dynamics and factors them into their valuation.</p>

<p>Comparing pricing across different CNC brands reveals that a quality 5-axis vertical machining center (VMC) typically costs <strong>$150,000 to $400,000</strong> new, with used units ranging widely. A standard 3-axis mill like the DNM400 remains valuable because many jobs don't need 5-axis capability, making it a practical, cost-effective workhorse for smaller shops and job operations.</p>

<h3>Why Getting an Accurate Appraisal Strengthens Your Position</h3>

<p>Whether you're buying or selling a DNM400, having a certified appraisal report gives you negotiating leverage. Sellers armed with a professional valuation can justify their asking price. Buyers use appraisals to avoid overpaying for machines that look good but carry hidden wear or maintenance issues.</p>

<p>For insurance purposes, an appraisal ensures your coverage matches your machine's actual replacement cost. For tax reporting, business valuation, or loan collateral, an appraiser's certified report carries legal weight that casual market comparisons simply don't.</p>

<p>If you're exploring <a href="https://www.example.com/blog/what-you-need-to-know-about-getting-an-equipment-and-machinery-appraisal">equipment and machinery appraisal</a> for the first time, you'll find the process straightforward. Work with an appraiser who specializes in <a href="https://www.example.com/blog/appraising-industrial-equipment-assessing-machinery-and-manufacturing-assets">industrial equipment</a> or <a href="https://www.example.com/blog/what-types-of-metalworking-equipment-are-usually-appraised">metalworking equipment specifically</a>. They'll ask detailed questions about your machine's history, run your photos and data through market analysis, and deliver a report that meets USPAP (Uniform Standards of Professional Appraisal Practice) standards—the same professional guidelines that govern real estate appraisals.</p>

<h3>Making Informed Decisions with Professional Guidance</h3>

<p>Whether you're acquiring your first CNC mill, managing a machine inventory for your shop, or planning to liquidate equipment, understanding your machine's true market value removes guesswork from the process. A professional appraisal of your <strong>Doosan CNC Mill DNM400</strong> gives you that clarity—backed by certified expertise, market research, and adherence to professional appraisal standards.</p>

<p>The investment in a proper appraisal typically pays for itself many times over. It protects you against underpricing when you sell. It ensures you're properly insured. It supports your tax filings and business valuation. And it demonstrates to buyers that you have nothing to hide—your machine's documented value and condition stand on their own merits.</p>

<div class="callout note"><p><strong>Key Takeaway</strong></p>

<p>A professional appraisal of your Doosan DNM400 provides the objective, market-backed valuation you need to buy, sell, or protect this valuable asset with confidence.</p></div>

<p>When you're ready to move forward, <a href="https://www.example.com/types/equipment-and-machinery">explore equipment and machinery appraisal services</a> tailored to industrial assets. If you operate metalworking equipment in your shop, <a href="https://www.example.com/blog/tips-to-make-the-most-of-your-metalworking-equipment-appraisal">learn more about how appraisals impact your operations</a>. And if you have questions about <a href="https://www.example.com/blog/what-documents-do-you-need-for-a-metalworking-equipment-appraisal">what documents you'll need</a>, we're here to guide you through every step.</p>

<p>Your DNM400 is a productive asset that deserves a fair, accurate, professional valuation. Let's help you get there.</p>