<h2>Understanding the Value of a Brother CNC Mill TC-S2A</h2>

<p>If you're considering selling, buying, or insuring a Brother CNC Mill TC-S2A, one of the first questions that comes to mind is likely: "What is it worth?" The answer depends on several interconnected factors—condition, operating history, included tooling, and current market demand all play significant roles in determining your machine's actual value.</p>

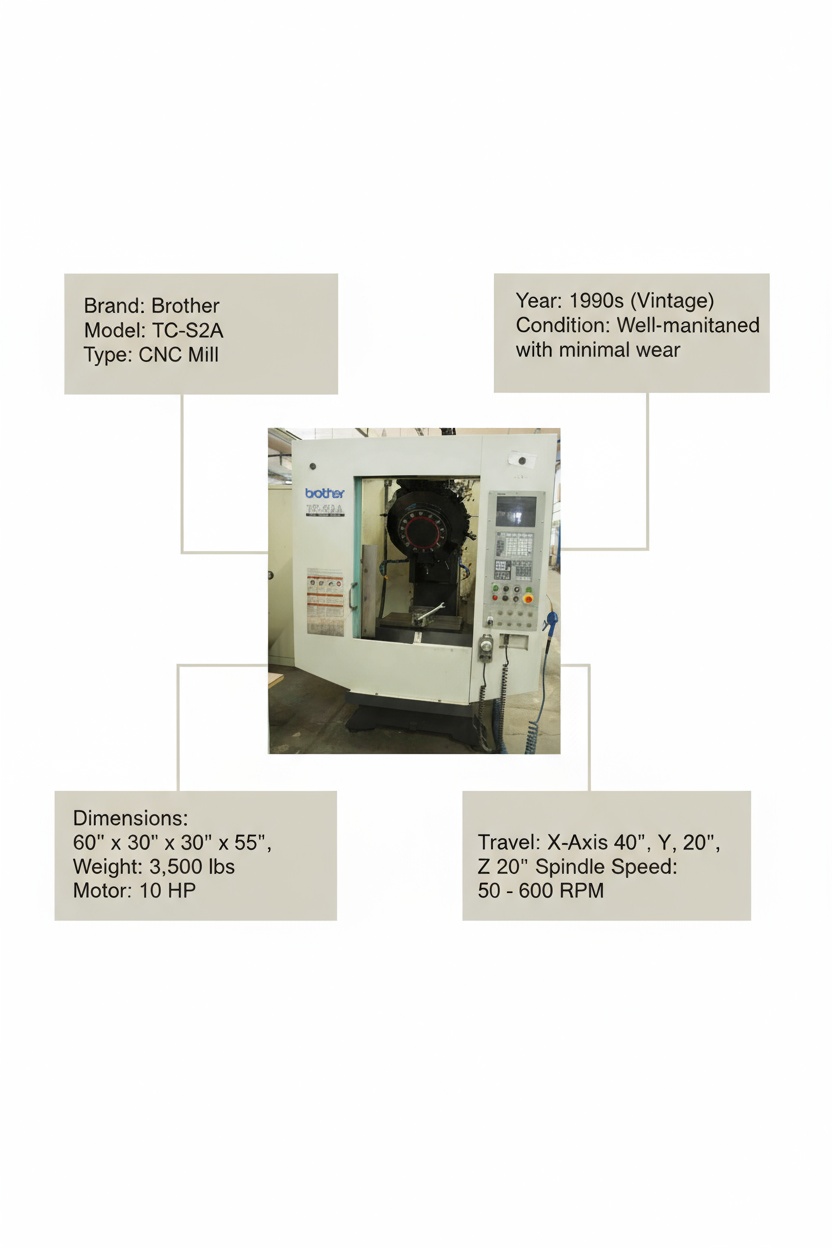

<p>This vintage CNC mill, built in the 1990s, remains highly valued in job shops, tool-and-die facilities, and prototyping operations. Understanding how appraisers value this equipment, what documentation you'll need, and how different use cases (sales, insurance, lending) influence the appraisal process will help you get a fair and defensible valuation.</p>

<div class="callout info"><p><strong>Did You Know?</strong></p>

<p>A Brother CNC Mill TC-S2A in good condition typically falls in the $50,000–$70,000 range, though machines with exceptional maintenance histories or valuable included tooling can command premium prices.</p></div>

<h2>Current Market Value and Pricing for the Brother CNC Mill TC-S2A</h2>

<p><strong>How much is a Brother CNC Mill TC-S2A worth today?</strong> The straightforward answer is that value depends on age, condition, operating hours, included options, tooling, and local demand. Used examples of this model commonly trade across a broad range—many fall between about $30,000 and $100,000—but a precise valuation requires professional inspection and current market comparables.</p>

<p>A well-maintained Brother TC-S2A with documented service history, minimal wear, and quality tooling typically commands valuations in the $50,000–$70,000 range. Machines with lower operating hours, recent upgrades, or specialized fixtures tend to appraise toward the higher end. Conversely, units needing significant repairs, missing documentation, or showing heavy wear may fall below $50,000.</p>

<p>The market for this equipment remains steady because the TC-S2A's robust construction, 10-horsepower motor, and solid spindle performance (50–6,000 RPM) make it a reliable workhorse for many manufacturing operations. Its 40-inch X-axis, 20-inch Y-axis, and 20-inch Z-axis travel provide adequate capacity for mid-range job shop work, which keeps resale demand consistent.</p>

<div class="callout tip"><p><strong>Pro Tip</strong></p>

<p>Document every service visit, calibration, and repair—maintenance records are often the single biggest driver of resale value and appraisal outcomes.</p></div>

<h2>What Information and Documentation Do You Need for an Accurate Appraisal?</h2>

<p><strong>What information should I gather to get an accurate appraisal for my Brother CNC Mill TC-S2A?</strong> This is a critical question because the more comprehensive your documentation, the faster and more reliable your appraisal will be.</p>

<p>Start by collecting the following essential items:</p>

<ol>

<li><strong>Serial number and manufacturing year</strong> – Establishes the machine's identity and age.</li>

<li><strong>Control model and software version</strong> – Important for feature set and upgrade potential.</li>

<li><strong>Operating hours or cycle counts</strong> – Shows usage intensity and remaining service life.</li>

<li><strong>Maintenance and calibration records</strong> – Demonstrates proper care and reliability.</li>

<li><strong>Recent repair invoices</strong> – Clarifies any past issues and their resolution.</li>

<li><strong>High-quality photographs</strong> – Capture the machine overall, control panel, spindle, tool changer, and any visible wear or damage.</li>

<li><strong>List of included tooling and fixtures</strong> – Accessory value adds meaningfully to the machine's worth.</li>

<li><strong>Software licenses and documentation</strong> – If included, licensed software increases resale value.</li>

<li><strong>Any modification or upgrade documentation</strong> – Helps appraisers understand whether changes were properly executed.</li>

</ol>

<p>For a <a href="/blog/what-documents-do-you-need-for-a-metalworking-equipment-appraisal">photo-based desktop appraisal</a>, this documentation typically takes 2–5 business days to process after submission. An on-site inspection generally takes 1–3 weeks to schedule, with a full report delivered 3–10 business days after the visit.</p>

<div class="callout note"><p><strong>Key Insight</strong></p>

<p>Missing documentation doesn't disqualify your appraisal, but it may result in a more conservative (lower) valuation because appraisers must account for uncertainty.</p></div>

<h2>How Appraisers Adjust Value for Condition, Modifications, and Tooling</h2>

<p><strong>How do appraisers adjust value for condition, modifications, and included tooling on a TC-S2A?</strong> Professional appraisers follow a systematic approach, assessing physical and mechanical condition, then applying adjustments for extras and drawbacks.</p>

<h3>Condition Assessment</h3>

<p>Appraisers rate the overall condition on a standard scale: excellent, good, fair, or poor. For a Brother TC-S2A, this includes:</p>

<ul>

<li><strong>Spindle noise and runout</strong> – A quiet, true spindle is critical to precision work and commands premium value.</li>

<li><strong>Axis movement and backlash</strong> – Smooth, responsive axes indicate proper maintenance and mechanical health.</li>

<li><strong>Paint, cosmetics, and visible wear</strong> – Heavy cosmetic wear may reduce value, though functionality matters more than appearance.</li>

<li><strong>Electrical and control system operation</strong> – Must be fully functional; obsolete or problematic control systems can significantly reduce value.</li>

<li><strong>Missing or worn parts</strong> – Damaged way covers, worn ballscrews, or missing guards reduce value and incur estimated repair costs.</li>

</ul>

<h3>Modifications and Upgrades</h3>

<p>Factory options and quality upgrades add to the machine's value:

- Added automatic tool changers or probe systems

- Upgraded spindles or servo drives

- Licensed CAM software or control system enhancements

- Recently rebuilt or refurbished subsystems</p>

<p>Conversely, nonstandard modifications, poor workmanship, or proprietary customizations that reduce compatibility may lower value. Appraisers carefully evaluate whether modifications enhance or detract from the machine's utility and resale appeal.</p>

<h3>Tooling and Included Assets</h3>

<p>Included tooling, work-holding devices, fixtures, and software licenses are separately valued and added to the base machine value. A Brother CNC Mill TC-S2A with a complete set of quality cutting tools, vises, collets, and probes may appraise $5,000–$15,000 higher than a bare machine.</p>

<h2>Valuation Approaches and When Appraisers Use Them</h2>

<p><strong>Which valuation approaches are used for a Brother CNC Mill TC-S2A and when?</strong> Professional appraisers typically employ one or more of three standard approaches: the market approach, the cost approach, and the income approach.</p>

<h3>Market Approach</h3>

<p>The market approach—comparing your machine to recent sales of similar equipment—is the most common method for standalone CNC machines. Appraisers research sales prices, auction results, and dealer listings for comparable Brother TC-S2A units, adjusting for differences in condition, hours, options, and location. This method is ideal when reliable market data is available and the machine is a standard model without unique revenue-generating capabilities.</p>

<h3>Cost Approach</h3>

<p>The cost approach estimates replacement cost—what it would cost to acquire an equivalent machine new, less physical and functional depreciation. This method is particularly useful for insurance valuations, where the goal is to determine the cost to replace the asset if it's lost or damaged. For a 1990s-era Brother TC-S2A, the replacement cost of a new, comparable mill might exceed $150,000, but significant depreciation applies due to age and the availability of used machines.</p>

<h3>Income Approach</h3>

<p>The income approach applies when the machine generates measurable revenue—for example, if your company operates a job shop and the mill generates billable production income. Appraisers calculate the net income attributable to the machine and capitalize it to arrive at value. This approach is less commonly used for standalone equipment but is valuable in business valuations where production capacity directly drives earnings.</p>

<p>Most appraisals for a Brother CNC Mill TC-S2A rely heavily on the market approach, with the cost approach used to validate or support the market value, especially for insurance purposes.</p>

<h2>Appraisal Fees, Standards, and Professional Credentials</h2>

<p><strong>What are typical appraisal fees for a CNC mill like the Brother TC-S2A?</strong> Fees vary by report type, intended use, and the appraiser's travel requirements.</p>

<ul>

<li><strong>Photo-based desktop appraisals</strong> typically range from about $200 to $700. These are ideal for general valuations, sales inquiries, or when you need a quick estimate.</li>

<li><strong>Full on-site inspections with USPAP-compliant reports</strong> usually range from $700 to $2,500 or more, depending on travel distance, complexity, and required certifications. These detailed reports are essential for lending, insurance claims, tax deductions, or litigation.</li>

</ul>

<div class="callout tip"><p><strong>Pro Tip</strong></p>

<p>Always specify your intended use (sale, insurance, lending, tax) when requesting an appraisal—it helps the appraiser prepare the right report type and ensure compliance with applicable standards.</p></div>

<h3>Professional Standards and Credentials</h3>

<p><strong>Will an appraisal for a Brother CNC Mill TC-S2A be accepted for lending, insurance, or tax purposes?</strong> Yes—provided the appraisal is performed by a credentialed professional and prepared to the appropriate standards.</p>

<p>For lending, insurance replacement, tax deductions, or legal proceedings, request a <strong>USPAP-compliant</strong> (Uniform Standards of Professional Appraisal Practice) report from an appraiser credentialed by one of these respected organizations:</p>

<ul>

<li><strong>American Society of Appraisers (ASA)</strong></li>

<li><strong>International Society of Appraisers (ISA)</strong></li>

<li><strong>Appraisers Association of America (AAA)</strong></li>

<li><strong>Certified Appraisers Guild of America (CAGA)</strong></li>

<li><strong>Association of Machinery and Equipment Appraisers (AMEA)</strong></li>

</ul>

<p>AppraiseItNow's <a href="/types/metalworking-equipment">national network of credentialed specialists</a> ensures your appraisal meets the highest professional standards, whether for a quick photo-based valuation or a comprehensive on-site inspection.</p>

<h2>Supporting Different Use Cases: Sales, Insurance, Lending, and Taxation</h2>

<p>Appraisals serve different purposes, and understanding which type you need will help you make an informed decision. Whether you're selling the machine, insuring it, using it as collateral, or claiming a tax deduction, the approach and documentation requirements differ slightly.</p>

<p><strong>For a sale or auction</strong>, a market-focused appraisal highlighting comparable sales, condition, and included tooling gives you and potential buyers a fair price anchor.</p>

<p><strong>For insurance replacement</strong>, an appraisal documents current fair market value and helps ensure your coverage limits are adequate. If a loss occurs, a documented appraisal strengthens your claim.</p>

<p><strong>For lending or collateral</strong>, a credentialed, USPAP-compliant appraisal is typically required by lenders. Banks and financial institutions want independent, defensible valuations to protect their interest.</p>

<p><strong>For tax purposes</strong>—such as estate valuations, charitable donations, or depreciation schedules—a detailed appraisal with supporting documentation provides the IRS-credible evidence you may need.</p>

<p>Our <a href="/blog/the-basics-of-equipment-and-machinery-appraisal">comprehensive guide to equipment and machinery appraisal</a> walks you through each scenario in more detail, helping you understand which appraisal type fits your situation.</p>

<h2>Transport, Reinstallation, and Condition Factors</h2>

<p><strong>What transport, reinstallation, and testing factors influence the value of a used TC-S2A?</strong> These practical considerations can significantly affect what a buyer is willing to pay and how appraisers adjust value.</p>

<ul>

<li><strong>Shipping risk and cost</strong> – Crating, rigging, and transporting a 3,500-pound CNC mill is expensive and risky. Appraisers consider whether shipping costs are the buyer's responsibility and factor in potential damage risk.</li>

<li><strong>Precision alignment and leveling</strong> – After transport, the machine must be carefully leveled and aligned. Any misalignment can compromise spindle runout and surface finish quality.</li>

<li><strong>Electrical and utility compatibility</strong> – Older machines may require 220V or 440V three-phase power. Ensuring the buyer's facility can support the machine's electrical needs affects its desirability.</li>

<li><strong>Calibration and run-in testing</strong> – A reputable seller often invests in post-move calibration and test runs, which adds value and reassures buyers.</li>

<li><strong>Available spare parts and technical support</strong> – Access to replacement ballscrews, servo drives, or manuals influences long-term ownership costs and perceived value.</li>

</ul>

<p>Machines recently reinstalled, tested, and certified in good working order often appraise higher than similar units in unknown condition. Conversely, if a machine requires significant work after relocation, appraisers deduct estimated remedial costs from the base value.</p>

<div class="callout note"><p><strong>Key Takeaway</strong></p>

<p>A Brother CNC Mill TC-S2A that's been well-maintained, properly transported, and tested after installation represents significantly lower risk to a buyer and will appraise higher than an "as-is" machine with unknown history.</p></div>

<h2>Making the Most of Your Brother CNC Mill TC-S2A Appraisal</h2>

<p>Getting an appraisal is just one step in your valuation journey. Whether you're selling, buying, insuring, or leveraging the machine for a business transaction, a professional appraisal provides the credible, defensible valuation you need.</p>

<p>Here's how to maximize your appraisal outcome:</p>

<ol>

<li><strong>Gather complete documentation</strong> – The more records you provide, the faster and more accurate the appraisal.</li>

<li><strong>Be transparent about condition and history</strong> – Appraisers uncover issues during inspection; honesty upfront builds trust and avoids surprises.</li>

<li><strong>Specify your intended use</strong> – Different uses require different report types and compliance standards.</li>

<li><strong>Ask about credentials and standards</strong> – Ensure your appraiser is credentialed by a recognized organization like ASA, ISA, or AAA.</li>

<li><strong>Consider both online and in-person options</strong> – Desktop appraisals are fast and affordable for straightforward valuations; in-person inspections add credibility for high-stakes transactions.</li>

</ol>

<p>For deeper insights into the appraisal process itself, our <a href="/blog/a-comprehensive-look-at-metalworking-equipment-appraisal">detailed guide to metalworking equipment appraisals</a> and <a href="/blog/tips-to-make-the-most-of-your-metalworking-equipment-appraisal">tips to make the most of your appraisal</a> offer practical strategies to strengthen your valuation.</p>

<h2>Why Professional Appraisal Matters for Your CNC Mill</h2>

<p>A Brother CNC Mill TC-S2A is a significant asset, often representing $50,000 or more in capital value. Whether you're making a purchase decision, protecting your investment through insurance, securing financing, or preparing for a sale, a professional appraisal from a credentialed, USPAP-compliant appraiser gives you the confidence and documentation you need.</p>

<p>Your appraiser becomes your advocate—someone who understands the machine's technical specifications, market demand, condition factors, and local buyer preferences. They can explain to potential buyers, lenders, or insurers exactly why your machine commands its valuation, backed by methodology, comps, and professional standards.</p>

<p>If you're ready to get your Brother CNC Mill TC-S2A appraised, <a href="/types/equipment-and-machinery">AppraiseItNow's network of credentialed machinery specialists</a> is here to help. We offer both quick photo-based assessments and comprehensive on-site inspections, all delivered with the professional rigor and expertise your valuable asset deserves.</p>

<div class="callout tip"><p><strong>Next Steps</strong></p>

<p>Gather your documentation (serial number, maintenance records, photos), specify your intended use, and reach out to start your appraisal today. A fair, credible valuation is within reach—and it all begins with the right appraiser on your team.</p></div>